Why Double Tube Sheet heat exchangers are essential in biopharmaceutical processes

Double Tube Sheet (DTS) heat exchangers are an engineering solution widely used in the biotechnological and biopharmaceutical industries. Their specialized Double Tube Sheet design provides an extra safety barrier that prevents cross-contamination between fluids, meeting the stringent sanitary requirements of processes such as vaccine production, cell bioprocessing, and injectable drug manufacturing. Below is a comprehensive technical guide on these devices, intended for professionals in the sector.

1. Technical definition of the double tube sheet exchanger

A Double Tube Sheet heat exchanger is a type of shell-and-tube heat exchanger that incorporates two parallel tube sheets at each end of the tube bundle, separated by a small gap or chamber. Each tube runs through both sheets and is fixed (by mechanical expansion and/or welding) to each one, creating a double sealing barrier at the tube-to-sheet joint. This design ensures that if a leak occurs in any tube or in its joint with the tube sheet, the fluids will not mix: the leaking fluid will remain confined within the space between the two tube sheets instead of entering the opposite circuit. In other words, any leakage will emerge into the intermediate chamber (usually open to the atmosphere) where it can be quickly detected, avoiding contamination of the fluid on the other side.

From a construction standpoint, the tube sheets (also known as tube plates) are perforated metal discs where the ends of the tubes are fixed. In the double-sheet design, two separate plates are used at each end: one connected to the head side (product) and the other to the shell side (utility). The space between the plates is usually vented or constantly drained to serve as a leakage detection zone. In this way, the DTS exchanger provides extra protection against leaks compared to a traditional single-tube-sheet design, by adding a second barrier and a relief zone where any fault can be identified before becoming a problem.

2. Detailed operating principle

In terms of heat transfer, a Double Tube Sheet heat exchanger operates under the same thermodynamic principles as a conventional shell-and-tube exchanger: typically, two fluids (product and utility) flow through separate paths (one inside the tubes and the other in the shell annulus), exchanging heat through the tube wall. Countercurrent flow is often used to maximize thermal efficiency. The DTS design stands out in how it handles a potential leak:

- Controlled leakage path: If a tube cracks or develops a pinhole, or if the joint between the tube and the internal sheet fails, the fluid would escape through the breach but would not enter the opposite circuit. Thanks to the double-sheet design, the fluid exits through the intermediate area (usually visible via an inspection or drainage port) rather than contaminating the fluid on the other side. For example, in a conventional water-to-water exchanger, a tube rupture might allow low-purity water to mix with high-purity water. In contrast, with a DTS design, the water would escape between the sheets and be immediately detected as an external leak, triggering alarms or inspections without any direct contact between both water streams.

- Early leak detection: The space between the two tube sheets is open to the atmosphere or connected to a detection system, so any leak creates a visible or measurable indication. It’s common to include a drain or a telltale port in this intermediate chamber, and even sensors (e.g., conductivity or liquid presence detectors) to alert the control system to an incipient leak. This allows maintenance personnel to respond quickly and repair the unit before cross-contamination occurs.

- Thermal and mechanical integrity: The addition of a second tube sheet also improves the mechanical integrity of the exchanger. Since a single sheet is not shared by both sides, mechanical and thermal stress at the joints is reduced during operation. The small gap between the sheets can partially absorb thermal expansion differences between the tubes and the shell, minimizing the risk of thermal fatigue cracks. Additionally, tubes are typically fixed to both sheets by hydraulic expansion or rolling, and often with seal welding on the outer sheet to ensure total tightness. These welds follow sanitary standards (e.g., ASME BPE) and are smoothly polished to eliminate pores or cracks where contaminants could accumulate.

In summary, a Double Tube Sheet exchanger delivers efficient heat transfer while ensuring complete fluid separation. Any internal leak is quickly isolated and signaled before causing contamination. For this reason, this design is considered fail-safe for applications where purity and containment are essential, such as in high-demand biopharmaceutical processes.

3. Applications in the biotech and biopharma industry

Double Tube Sheet heat exchangers are most commonly used in sectors where product integrity and contamination prevention are critical. In biotechnology and biopharmaceuticals, they are typically used in:

- High-purity water systems: They are ideal for Water for Injection (WFI) and Purified Water (PW) services, both in their generation stages and distribution loops. For example, WFI storage tanks often use DTS exchangers to keep the water circulating hot or to cool it before points of use, ensuring that the injectable water is never compromised by the utility fluid (typically industrial steam, cooling water, or another thermal medium).

- Pure steam generation and pharmaceutical distillation: In WFI distillers and clean steam generators, using an evaporator or condenser with a Double Tube Sheet design is practically standard. This ensures that the heating industrial steam never mixes with the purified water or produced distillate. For example, multi-effect distillers often include DTS exchangers in each effect to isolate the motive steam from the sterile water. Likewise, in final clean steam condensers, a Double Tube Sheet prevents the cold (non-sterile) water from contaminating the pure steam condensate.

- Heating/cooling loops in aseptic processes: Double Tube Sheet exchangers are commonly implemented in the thermal circuits of bioreactors, fermenters, and aseptic tanks, where a utility fluid (hot/cold water, glycol, clean steam, etc.) controls the temperature of the culture or product. With the DTS design, it’s guaranteed that the utility fluid (which may contain additives or lack sterility) will not enter the bioreactor even in the event of a failure, protecting the cell culture or biological solution. Many pharmaceutical plants install these exchangers in their thermal control systems specifically to avoid cross-contamination during fermentation or cell cultivation.

- Formulation and sterile finish processes: In vaccine, injectable drug, and recombinant protein production, there’s often a need to heat or cool product solutions indirectly. A typical case is the rapid cooling of sterile solutions after sterilization (e.g., cooling a sterile saline solution before vial filling). Here, a conventional shell-and-tube exchanger would risk having the cooling fluid (e.g., tower water or glycol) contaminate the sterile solution in case of a leak. For this reason, Double Tube Sheet designs or equivalent alternatives are used to ensure that the pharmaceutical product never comes into contact with the cooling medium. GMP standards may even require this type of design in certain applications; for example, FDA guidelines for large-volume parenterals indicate that if a welded concentric double-tube or Double Tube Sheet exchanger is not used, a pressure differential with alarms must be maintained to prevent undetected leaks, demonstrating the regulatory preference for DTS designs in such cases.

- Clean-in-Place (CIP) and Sterilization-in-Place (SIP): CIP systems that recirculate hot detergent solutions to clean process equipment sometimes use heat exchangers to heat those solutions. In critical applications, these exchangers may also be of the Double Tube Sheet type, preventing the cleaning solution (which may contain aggressive chemicals) from mixing with the heating medium. Likewise, some SIP systems (in-situ steam sterilization) incorporate DTS exchangers to generate pure steam from industrial steam, thus protecting the quality of the sterile steam.

In summary, typical applications cover any scenario where mixing two fluids of different qualities must be absolutely avoided. This includes pharmaceutical water loops (PW/WFI) in biopharma plants, media and buffer preparation units, aseptic production equipment for vaccines and biologics, and even high-end food applications (e.g., pasteurization of sensitive products). Their use has become standard in facilities where the purity of the product-side fluid is critical, providing peace of mind for engineers and compliance for regulatory audits.

4. Advantages compared to other types of heat exchangers

- Cross-contamination prevention: The primary reason for using a DTS design is to prevent fluid mixing in the event of an internal leak. Unlike a traditional single-tube-sheet shell-and-tube exchanger, where a perforation in a tube can go unnoticed and contaminate the product, the Double Tube Sheet design inherently eliminates the risk of cross-contamination. This feature is crucial in industries where fluid mixing could lead to severe consequences (production batch loss, patient risk, etc.). Even compared to gasketed plate exchangers, DTS offers greater safety, since in plate systems a deteriorated gasket or cracked plate could allow undetected fluid crossover. In contrast, DTS provides a dual physical barrier and a visible leak point, practically eliminating the chance of unnoticed contamination.

- Instant leak detection: Double Tube Sheet exchangers act as an "early warning" system in the event of failure. Any leak exits externally through the inter-sheet space, where it can be visually identified or quickly detected. In other designs, additional instrumentation (e.g., continuous differential pressure or conductivity monitoring) is needed to infer a possible internal leak. With DTS, the construction itself serves as passive detection. This simplifies safety protocols: many facilities rely on regular visual inspection of the port between sheets or a basic sensor in that chamber, which is more straightforward and reliable than interpreting pressure differences between flows. Thus, if a failure occurs, it’s immediately known and addressed before the process is compromised.

- Compliance with regulations and GMP: The Double Tube Sheet configuration helps companies comply with the strictest regulatory standards. Agencies such as the FDA, EMA, and standards like ASME BPE recognize the benefits of this design. For instance, the FDA lists it as an acceptable design without additional measures in Water for Injection systems. Many GMP audits expect to see this type of exchanger at critical points. By choosing DTS, quality and engineering departments ensure their equipment is aligned with best industrial practices, avoiding observations related to potential cross-contamination. Furthermore, the design simplifies qualification: during the validation stage, it’s easier to justify that the contamination risk is virtually null thanks to the double sheet (reducing the need to demonstrate additional risk control measures).

- Ease of maintenance and inspection: Although a two-sheet exchanger might initially seem more complex, it actually simplifies maintenance. Immediate leak detection means the equipment is rarely operated with hidden defects; the affected tube or joint is repaired as soon as the leak is identified, preventing larger damage or extended contamination. Also, many sanitary DTS designs allow easy access to the tube bundle by simply disassembling the heads, making cleaning and inspection of the product side straightforward. Unlike plate exchangers, which require disassembly of an entire plate pack and replacement of dozens of gaskets for thorough inspection, a Double Tube Sheet shell & tube requires removing just a few head bolts to visually inspect the tubes and internal sheet. The absence of numerous gaskets also reduces maintenance consumables. DTS systems are CIP/SIP compatible, allowing cleaning without disassembly, which streamlines preventive maintenance routines.

- Other technical benefits: Double Tube Sheet exchangers may also incorporate other hygienic design advantages. For example, many pharmaceutical models use U-tubes to absorb thermal expansion, reducing mechanical stress, and allow complete drainage in both circuits, avoiding dead legs where liquids could stagnate. These units offer thermal performance comparable to any well-designed tubular exchanger, so adding the double sheet does not compromise heat transfer efficiency, it simply adds safety. In short, it offers the best of both worlds: high thermal efficiency and maximum sanitary safety.

It’s worth noting that the main disadvantage of DTS exchangers compared to simpler options is the higher initial cost and slight increase in manufacturing complexity. However, in the biopharmaceutical context, these costs are easily justified by the savings in contamination risk, product recalls, and regulatory compliance. Compared to the alternative of installing differential pressure monitoring systems or duplicating equipment, the Double Tube Sheet design is often the most robust and reliable long-term solution for avoiding cross-contamination.

5. Conclusion

The Double Tube Sheet (DTS) heat exchanger represents an essential solution in environments where product integrity is critical, as in biotechnological and pharmaceutical processes. Its Double Tube Sheet design ensures physical separation between fluids, immediately detects any leakage, and significantly reduces the risk of cross-contamination. These features make it a highly valued piece of equipment for Water for Injection production, cell cultivation, sterile formulations, and thermal loops in bioreactors.

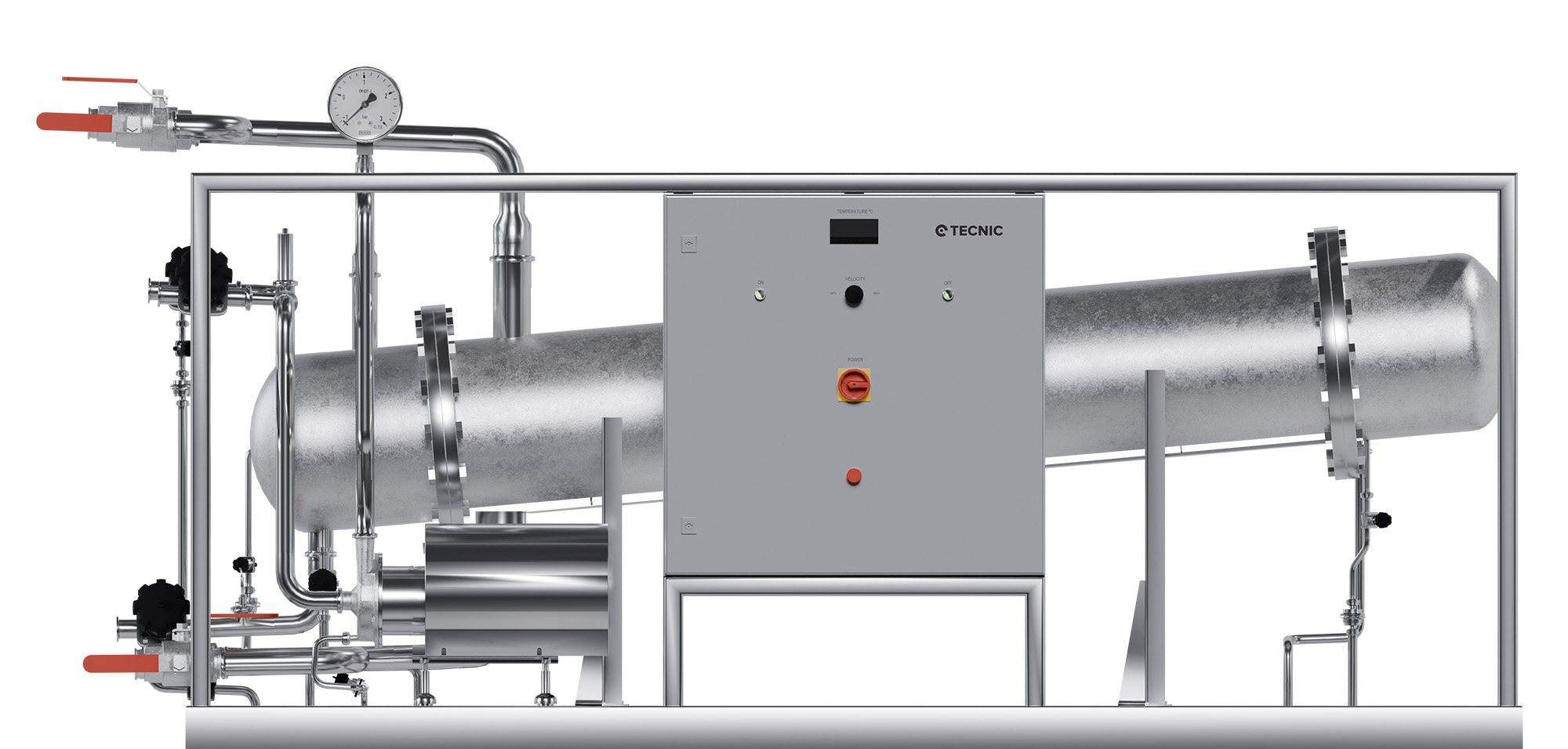

At TECNIC, we integrate the DTS heat exchanger as part of our solutions for GMP environments. Its implementation responds not only to regulatory requirements but also to our commitment to process quality and final product safety. Thanks to this type of technology, our solutions ensure not only high thermal performance but also maximum confidence in the critical operations of our clients.

Frequently Asked Questions (FAQ)

It’s a shell-and-tube heat exchanger with two separate tube sheets that prevent cross-contamination between fluids.

To ensure sterile fluid separation and early leak detection in critical applications like WFI, pure steam, and vaccine production.

Leaks are diverted to a vented chamber between tube sheets, allowing visual or sensor-based detection before contamination occurs.

Yes, Double Tube Sheet designs are recognized by FDA and other regulatory bodies as best practice for avoiding contamination in pharmaceutical systems.

High-purity water, clean steam, product solutions, and utility fluids like industrial steam or glycol.

No. Double Tube Sheet exchangers offer easier inspection and fewer gaskets, often simplifying maintenance tasks.

No. These exchangers maintain excellent thermal performance while enhancing safety and reliability.