Smart Biotech Solutions to scale from lab to production with confidence.

Lab-scale solutions for Bioprocessing

Single-use & multi-use Bioreactors and TFF systems for lab-scale processes. Suitable for mAbs, vaccines, recombinant proteins, and cell & gene therapy. Volumes up to 10 L | Membrane area up to 0.7 m².

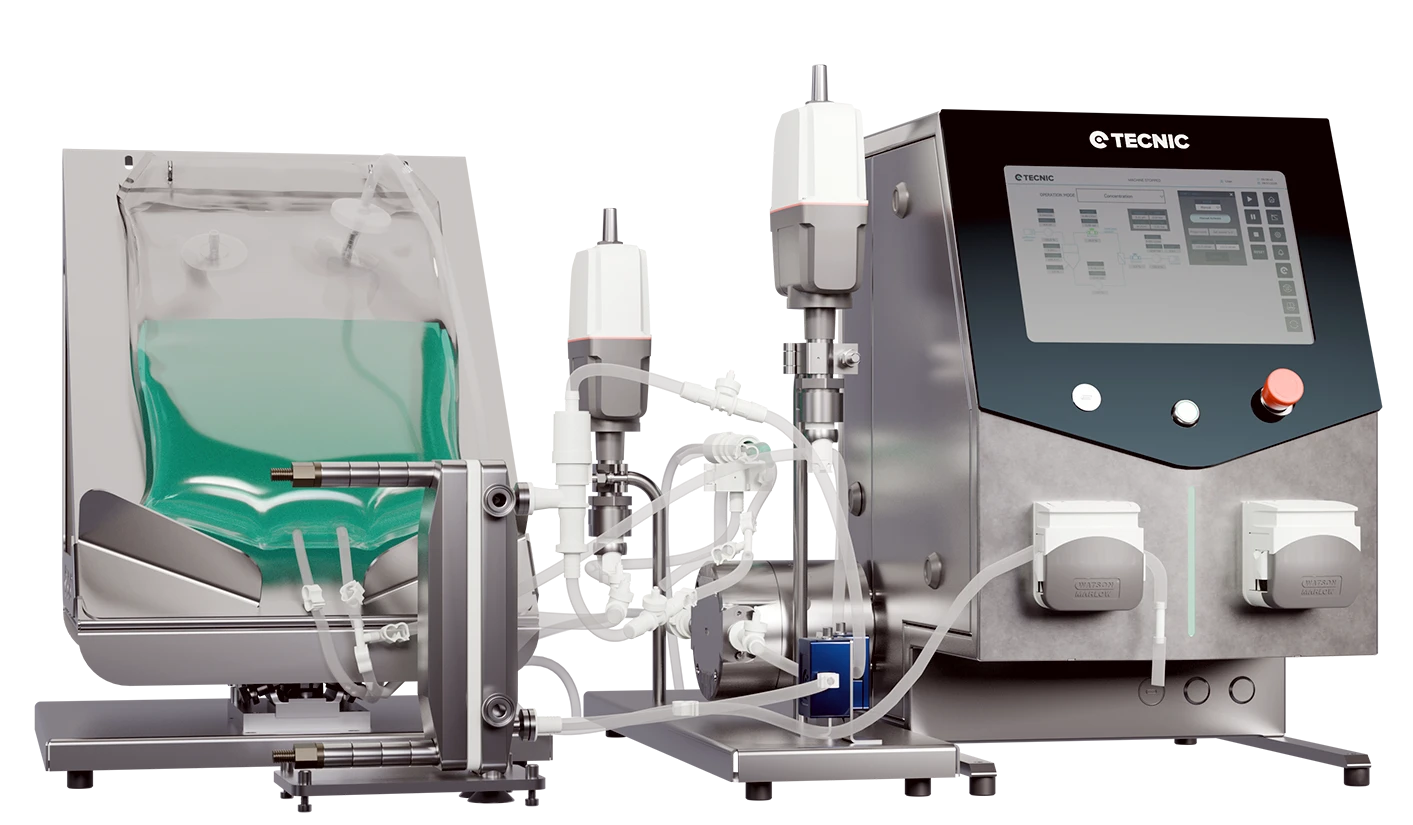

eLAB TFF Single-Use

Compact TFF system designed for lab-scale concentration and diafiltration processes. Single-use flow path ensures quick setup and easy cleaning.

Membrane area: up to 0.7 m²

Compact TFF system designed for lab-scale concentration and diafiltration processes. Single-use flow path ensures quick setup and easy cleaning.

Membrane area: up to 0.7 m²

Pilot-scale solutions for Bioprocessing

Single-use & multi-use TFF systems, Bioreactors, and supplies for process development and scale-up. Designed for mAbs, vaccines, and recombinant protein production. Volumes up to 50 L | Membrane area up to 2.5 m².

ePilot Bioreactor SU

Dual-use single-use bioreactor for pilot-scale applications. Suitable for both microbial and cell culture processes, combining flexibility and scalability with reduced cleaning needs.

Volumes: 30 to 50 L

Dual-use single-use bioreactor for pilot-scale applications. Suitable for both microbial and cell culture processes, combining flexibility and scalability with reduced cleaning needs.

Volumes: 30 to 50 L

ePLUS SU Mixer

Single-use mixing system for media and buffer preparation. Designed for fast setup, efficient mixing, and reduced cleaning time.

Volumes: 50 to 500 L

Single-use mixing system for media and buffer preparation. Designed for fast setup, efficient mixing, and reduced cleaning time.

Volumes: 50 to 500 L

eBAG 3D Mixer

Single-use 3D mixing bag for efficient homogenization of media and buffers. Designed for closed systems with bottom magnetic stirring and top handle for easy handling.

Volumes: 50 to 500 L

Single-use 3D mixing bag for efficient homogenization of media and buffers. Designed for closed systems with bottom magnetic stirring and top handle for easy handling.

Volumes: 50 to 500 L

ePilot Bioreactor MU

Multi-use bioreactor for pilot-scale microbial and cell culture processes. Designed for process development and scale-up with full automation and control.

Volumes: 30 to 50 L

Multi-use bioreactor for pilot-scale microbial and cell culture processes. Designed for process development and scale-up with full automation and control.

Volumes: 30 to 50 L

ePLUS CIP

Automated Clean-in-Place system designed for cleaning tanks, bioreactors, and process lines. Ensures consistent cleaning performance with customizable recipes.

Volumes: up to 2,000L

Automated Clean-in-Place system designed for cleaning tanks, bioreactors, and process lines. Ensures consistent cleaning performance with customizable recipes.

Volumes: up to 2,000L

Production-scale solutions for Bioprocessing

Single & multi-use Bioreactors, TFF systems and process supplies for large-scale bioproduction. For mAbs, vaccines, recombinant proteins. Volumes up to 2000 L | Membrane area up to 65 m².

eProd Bioreactor SU

Single-use bioreactor for large-scale microbial and cell culture processes. Designed for commercial manufacturing with advanced control and scalable configuration.

Volumes: up to 4,000 L

Single-use bioreactor for large-scale microbial and cell culture processes. Designed for commercial manufacturing with advanced control and scalable configuration.

Volumes: up to 4,000 L

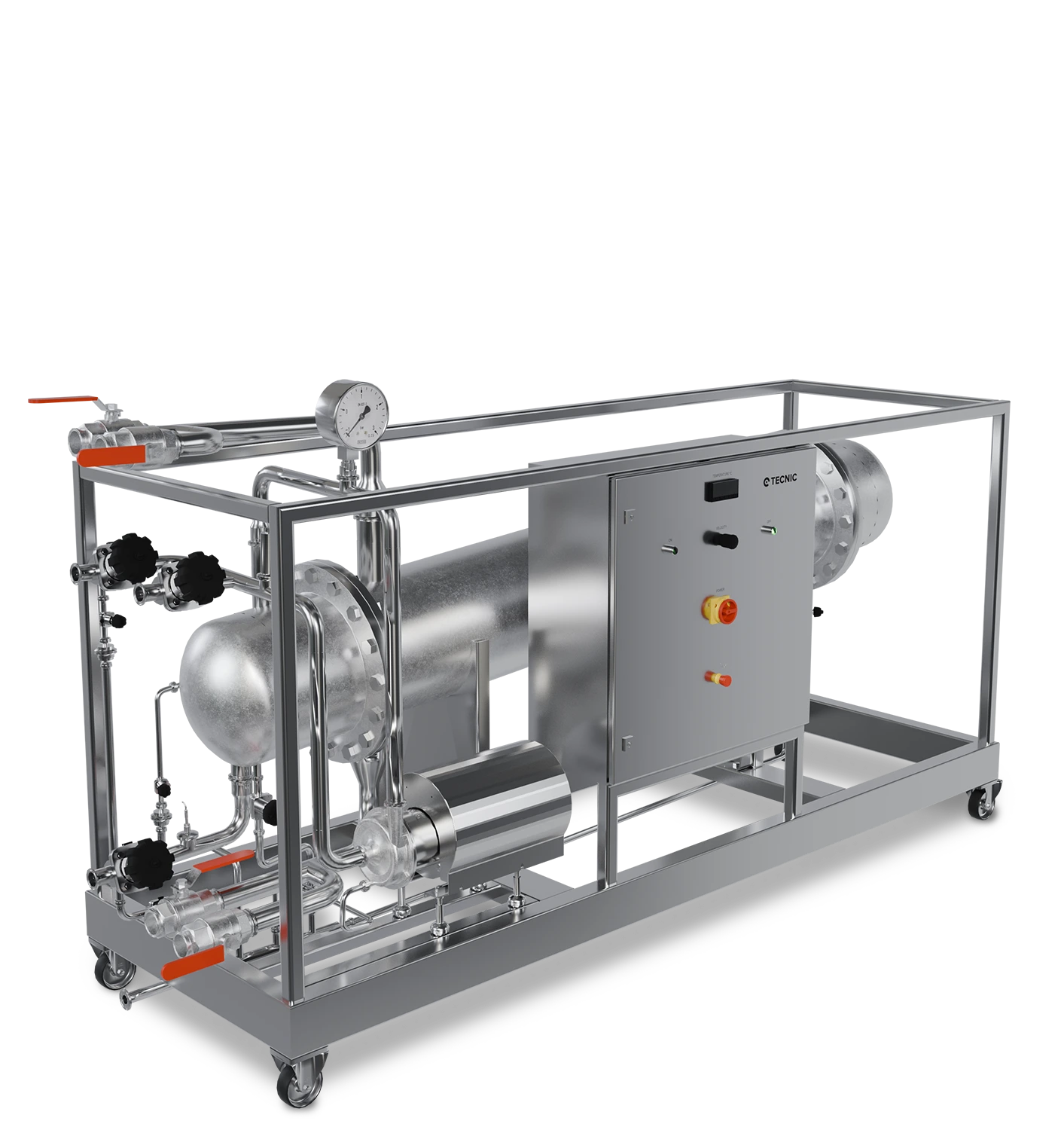

eProd TFF

Multi-use TFF system for large-scale concentration, clarification, and diafiltration. Compatible with cassette, hollow fiber, and ceramic membranes.

Membrane area: up to 65 m²

Multi-use TFF system for large-scale concentration, clarification, and diafiltration. Compatible with cassette, hollow fiber, and ceramic membranes.

Membrane area: up to 65 m²

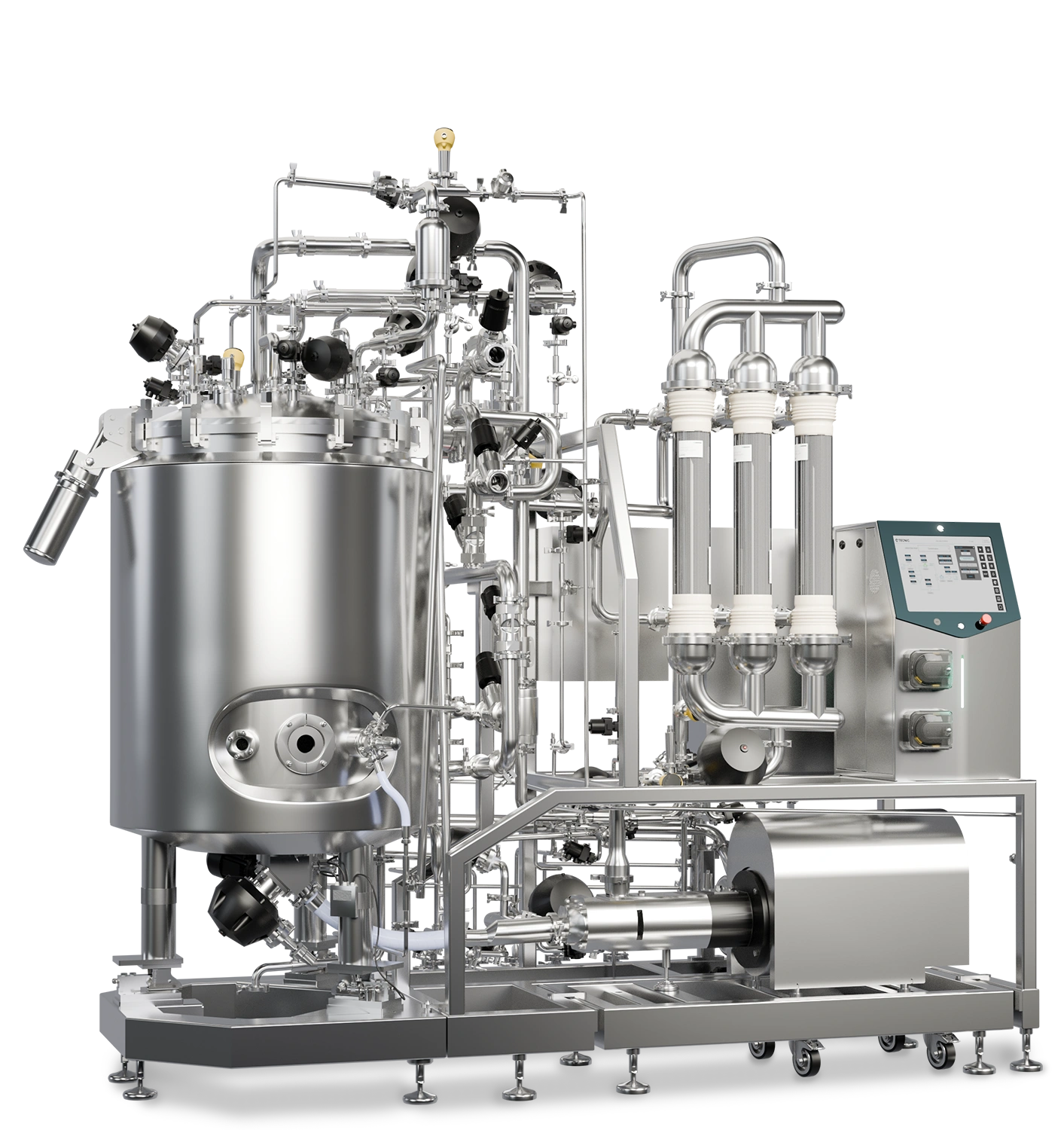

eProd Bioreactor MU

Multi-use bioreactor for large-scale bioproduction. Designed for microbial and cell culture processes with stainless steel vessels and integrated control systems.

Volumes: up to 2000 L

Multi-use bioreactor for large-scale bioproduction. Designed for microbial and cell culture processes with stainless steel vessels and integrated control systems.

Volumes: up to 2000 L

eBAG 3D STR

Single-use 3D bag designed for stirred-tank bioreactors. Optimized for cell culture applications with bottom magnetic stirring and top ports for secure integration.

Volumes: 30 to 1000 L

Single-use 3D bag designed for stirred-tank bioreactors. Optimized for cell culture applications with bottom magnetic stirring and top ports for secure integration.

Volumes: 30 to 1000 L